Quick Facts

| Challenge | Improve overall part quality and reduce manual hand work. | ||

| Solution | Thanks to the flexible diaphragm of the Triform press, parts are produced with a smooth, uniform, scratchfree surface, typically requiring no additional finishing. By eliminating the need for secondary buffing, polishing and other hand work, labor costs have been significantly reduced. | ||

| Challenge | Reduce tooling production time and cost. | ||

| Solution | Thanks to single tool technology, sheet hydroforming presses can reduce tooling costs by 50% to 90% compared to conventional presses. There is no need for a mated die to the punch (male die), as the flexible diaphragm in the machine acts as a universal female. Additionally, sheet hydroforming tooling can be manufactured from standard, inexpensive materials and typically has a longer life than conventional press tooling, due to the steady, uniform pressure applied during the process. | ||

| Results | Within the first year of operation, Steelville transferred over 34 parts just from their press brake. They’ve also won several bids based on the reduced tooling expense and fast forming times of the press. | ||

| Max Chamber Pressure | 5,000 PSI | ||

| Industry | Aerospace | ||

| Forming Area | 24" Diameter | ||

| Form Tool Clearance | 5" | ||

| Daylight | 6" |

Located in Steelville, Missouri, Steelville Manufacturing Co. is a leading aerospace parts supplier specializing in milling, turning, waterjet cutting and metal forming. They had been using traditional forming methods for decades to supply parts to OEM’s including Boeing, Lockheed Martin and Sikorsky.

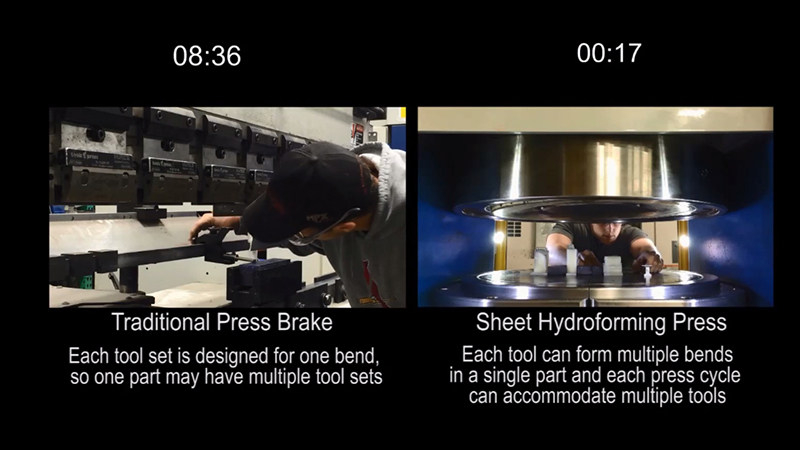

Steelville needed a modern forming solution that would improve net shape forming capability and reduce hand-finishing work. The engineering and machining time required for the production of their traditional male/female die sets was significant, and the new forming solution needed to reduce their investment in both engineering time and machining hours.

Beckwood evaluated Steelville’s needs and recommended a Triform Fluid Cell Sheet Hydroforming Press, featuring a 24” forming area. Today, the Triform 24-5FC accommodates the vast majority of Steelville’s aerospace parts, yet is compact enough to require minimal floor space (less than 10’ x 5’). Operation is straightforward, with new operators gaining machine fluency in minutes.

The nature of the Triform process results in tool changes that literally take seconds! Additionally, tooling costs are greatly decreased over traditional forming processes since the flexible bladder acts as a universal die half.

Within the first year of operation, Steelville transferred over 34 parts just from their press brake. They’ve also won several bids based on the reduced tooling expense and fast forming times of the press.

The Triform press also allows Steelville to use 3D printed tooling in their metal forming process. By using additive manufactured tools along with the Triform press, Steelville can bypass their machining centers all-together. This collaboration has dramatically shortened the turnaround time for new part production while driving down Steelville’s overall cost per part.

“We had been forming parts for years which we now know were tailor-made for the Triform,” Steelville Engineer Joseph Dust. “The addition of the 24-5FC definitely makes forming those parts much easier. With Triform, the overall time required for the completion of our tools has been cut in half!”

Read the article highlighting Steelville’s use of 3D printed pools in Metalforming Magazine

Speak to an engineer about sheet hydroforming