Beckwood uses energy efficient press technologies so that your machinery works harder without costing you more. With technologies like pneumatic dwell, soft starters, and servo actuators, your new machinery will pay for itself sooner than you might think. We focus on sustainable technology because it plays a significant role in curbing the environmental impact of our company and our machines, and we continually work with our partners to implement energy efficient press technologies that enable customers to enhance their manufacturing processes while decreasing energy consumption, scrap, noise pollution, and emissions.

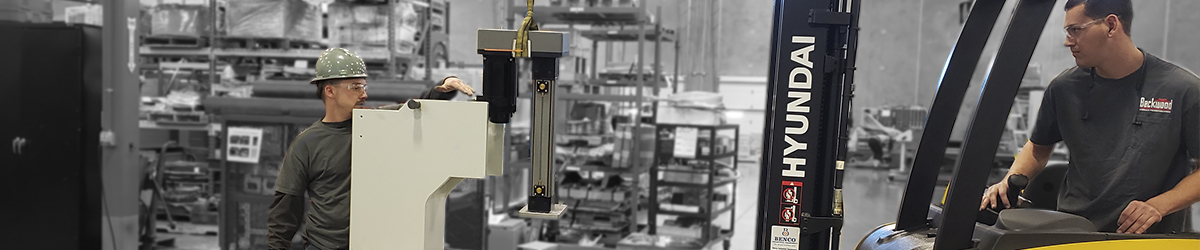

Servo-Electric Actuators

Beckwood offers both standard and custom presses powered by servo-electric actuators. Since servo-driven presses use an electricity instead of hydraulics to control ram movement, oil leaks, high energy consumption, and lengthy downtime are a thing of the past. Additionally, the roller-screw design within our actuators ensures your actuator will last up to 15x longer than traditional ball-screw actuators.

Variable Frequency Drive (VFD)

A Variable Frequency Drive (VFD) is a motor controller that allows the frequency and voltage supplied to an electric motor to vary based on the requirements of the press load. Beckwood presses with VFD technology offer dramatically increased energy efficiency when compared to traditional hydraulic systems because the VFD draws energy ‘on demand’. This ability to vary the energy output, by rotating the motor only as needed, also greatly reduces noise levels.

VFD Technology allows the user to monitor pump efficiency directly through the press’ HMI. Signs of decreased efficiency and premature pump wear can be detected early, aiding in the prevention of unexpected pump failures and unplanned downtime. Beckwood customers have the ability to set their own acceptable pump performance standards, thereafter receiving warning notifications if the pump’s performance falls outside the specified range.

Pneumatic Dwell

Beckwood’s Pneumatic Dwell System is an ideal solution for manufacturers looking to save energy during long dwell cycles. A small pneumatically-powered hydraulic pump is integrated into the hydraulic circuit, allowing the primary electric motor and pump to be ‘turned off’ during the dwell cycle. This minimizes electrical power consumption and reduces operating noise.

In a typical operation, the press’ primary electric motor and pump are used to close the tool/mold and develop the appropriate ram force. Once ram force is established, a pressure lock valve is used to hold the desired pressure in the cylinder(s). Over time, if a drop in pressure occurs as sensed via a pressure transducer, the pneumatic pump reacts by adding additional pressure back into the cylinder circuit to reach the desired force. The system functions ‘on demand’ and requires very little shop air.

Soft Starter

A soft starter protects the motor and ancillary equipment by limiting the initial in-rush of current and reducing the mechanical shock generated during startup. By gradually ramping-up the motor’s speed instead of accelerating it using a full voltage connection, you decrease the mechanical stress on the motor and shaft, extending the life of your equipment.

Soft starters are the economical choice for applications requiring speed control during motor start-up. Since they require less space than variable frequency drives, they are the ideal solution for presses with space limitations. Beckwood installs soft starters on hydraulic press with a motor larger than 100HP. Upon request, however, they can be added to motors of any size.

Get a quote to add energy efficient technology to your existing press