Are you looking for ways to improve your production process and save time on complex metal forming? Look no further than our TRIFORM line of press equipment.

Our TRIFORM technology offers numerous benefits for manufacturers including increased efficiency, reduced production time, and improved product outcome, proving that product quality and shorter production time can go hand in hand.

While our TRIFORM sheet hydroforming and deep draw hydroforming equipment have undoubtedly made their mark on the precision forming industry, today we will be highlighting two of our specialty TRIFORM configurations: ring expanders and stretch forming equipment.

Discover the advantages of these specialty presses and find out how Beckwood’s ring expanders and stretch forming equipment can help you streamline your production process.

What Are Ring Expanders?

Part of the TRIFORM line of metal forming equipment includes ring expanders. Ring expanders are tools used to quickly size metal rings into a precise round with a larger diameter. Shaping rings with other methods such as rolling and machining has proven to be a challenge, especially when it comes to maintaining the ring’s thickness and uniformity. Ring expanders minimize the risk of deformation during the shaping process.

How Do Ring Expanders Work?

Ring expanders consist of a concentric set of expanding mandrels or cones, powered by hydraulics and operated by a control panel. In cases where a customer needs to shape multiple sizes of rings, the ring expander may have a stack of different sized or stepped mandrels to accommodate different ring sizes. A metal ring is placed on this stack at the desired point, typically equal to or just smaller than its inner diameter. At this point, a hydraulic powered cylinder in the center of the machine forces the jaws on the mandrel to expand simultaneously, applying equal pressure to the inside of the ring in all directions. This stretches the initial form into a larger ring with a uniform diameter and wall thickness which is typically used in precision applications such as piston rings and aircraft components.

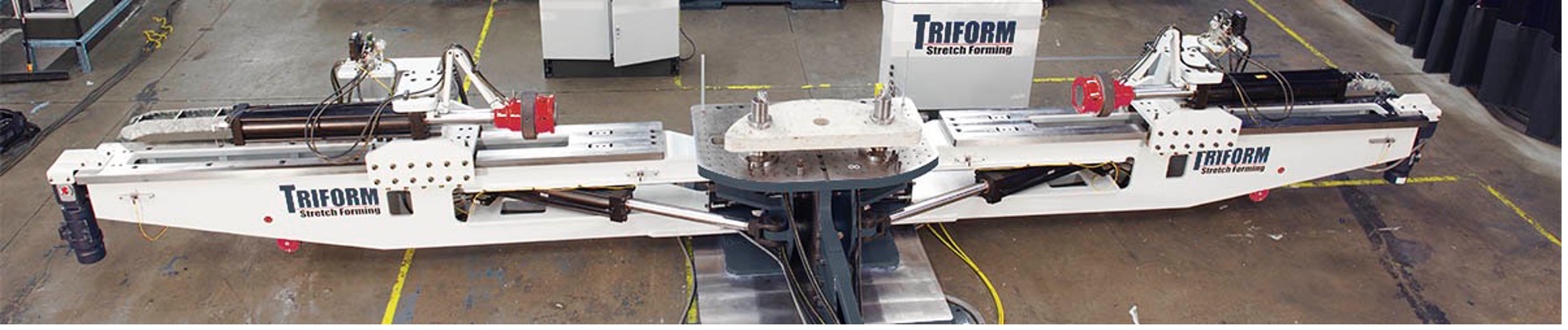

What Is Stretch Forming Equipment?

Stretch forming equipment is designed to take advantage of the physical properties of metal under tension. As the name implies, this type of equipment stretches a sheet or strip of metal to the point that it exceeds its inherent elastic limit. This allows the metal to be stretched around a die into its final shape, simplifying what would normally be a series of complex forming processes into just a single step. Stretch forming as a process is similar yet opposite to sheet hydroforming; where sheet hydroforming pushes a metal blank into shape, stretch forming instead pulls the blank into its final form.

How Does Stretch Forming Equipment Work?

In stretch forming, the edges of a metal blank are clamped between a series of jaws. The metal sheet or blank is then stretched to maintain a constant, uniform tension across the entire area of material. Once the blank has reached sufficient tension, a die is pushed against the blank with a hydraulic block, in the case of sheet stretch forming, or a moving hydraulic table, in the case of extrusion stretch forming. The die is then removed from the blank, which has been formed into a near-net finished part. Sheet stretch forming is used to form large, complex body components for the aerospace industry, while extrusion stretch forming is more commonly used for structural support pieces.

Advantages of Specialty TRIFORM Equipment

Increased Efficiency

One of the main advantages of our specialty TRIFORM equipment is its efficiency. Unlike traditional metal forming methods such as metal stamping, ring expanding and stretch forming do not require multiple steps or tooling changes to achieve the desired complex shape. The highly specialized design of each press allows parts to be created with just a single unmated tool. This means that manufacturers can produce complex parts in a single step, reducing production time and costs.

Reduced Production Time

Our specialty TRIFORM equipment also offers a significant reduction in production time. As mentioned, the process eliminates the need for multiple steps and tooling changes, which can significantly slow down production.

Furthermore, these presses can produce parts with a high level of accuracy and precision, reducing the need for additional finishing processes. This results in faster production times and a quicker time to market for your products.

Improved Product Quality

Finally, our ring expanders and stretch forming presses also offer improved product quality compared to traditional metal forming methods. These processes enables the production of complex shapes and intricate details that may not be achievable with other methods. This enables manufacturers to create high-quality, lightweight parts that meet the strict requirements of industries such as aerospace and defense.

Discover the right TRIFORM equipment for your forming operations!

Get in touch with the Beckwood team today.

Contact Beckwood Press

Beckwood Press: A Leader in Specialty Metal Forming Equipment

Beckwood Press is a leading manufacturer of specialty metal forming equipment, offering models such ring expanders and stretch forming machines. Our equipment is known for its precision, reliability, and efficiency, making it a top choice for manufacturers in various industries.

Our TRIFORM equipment is designed with advanced features such as programmable pressure and precision stroke control to ensure consistent and accurate forming. We also specialize in providing a wide selection of customizable options to meet the specific needs of each customer.

Real-World Examples of TRIFORM Equipment in Action

Automotive Industry

TRIFORM equipment has revolutionized the production of automotive parts, particularly in the exhaust system. By using ring expanders, manufacturers can quickly produce piston rings with a consistently high quality.

Aerospace Industry

The aerospace industry also benefits greatly from TRIFORM technology. Stretch forming equipment is used to create complex and lightweight parts, such as wing skins and fuselage components, with a high level of precision and accuracy.It is also ideal for production of heavier aircraft engine components.

Defense Industry

Stretch forming presses can be used to create complex and lightweight parts for defense applications, such as armored vehicles, military aircraft, and naval vessels. The advantages of stretch forming make it an ideal choice for creating lightweight yet durable parts for defense equipment. Additionally, the elimination of multiple steps and tooling changes in the process results in faster production times and cost savings. By incorporating stretch forming into their production processes, defense manufacturers can enhance their capabilities and deliver superior products for military applications.

Think stretch forming might be the manufacturing process for you?

Check out our standard extrusion forming models, or request a quote for a custom press!

View Our Models

How to Incorporate TRIFORM Equipment into Your Production Process

If you’re interested in incorporating our TRIFORM ring expanders and stretch forming equipment into your production process, here are a few key steps to follow.

Assess Your Needs

The first step is to assess your production needs and determine if ring expanding or stretch forming is the right solution for your business. Consider factors such as the complexity of your parts, production volume, and desired level of precision.

Choose the Right Equipment

Once you’ve determined the right choice for your business, it’s essential to choose the right equipment for the job. Consider factors such as the type of equipment (ring expander or stretch forming machine), the size and capacity of the equipment, and any customizable options that may be available.

Partner with a Trusted Manufacturer

Partnering with a trusted manufacturer like Beckwood Press is crucial for a successful part forming process. We can provide expert guidance on equipment selection, customization options, and ongoing support and maintenance.

To learn more about TRIFORM equipment and how it can help your business save production time, contact Beckwood Press today. Our team of press machinery experts can help you find the right solution for your production needs and guide you through the process of incorporating ring expanders and stretch forming equipment into your operations.