| Tonnage | 30 | ||

| Application | Bulge Forming | ||

| Industry | Safety | ||

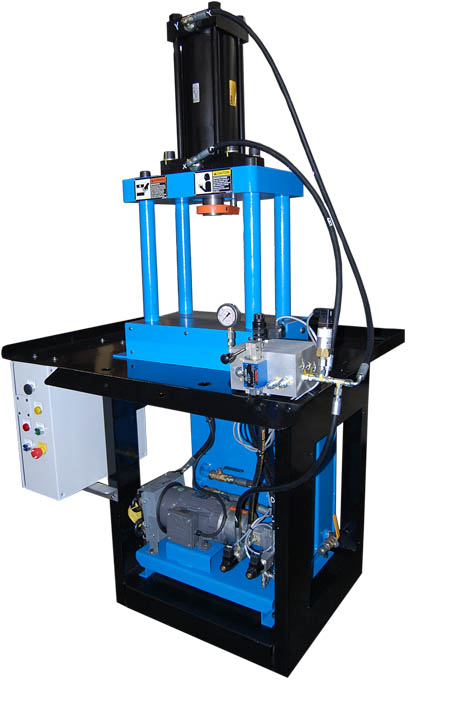

| Frame Style | 4-Post, Benchtop | ||

| Special Features | • Cylinder rod machined to accommodate existing tooling • TEFC motor mounted oil cooler | ||

| Intended Use | Used to bulge form rupture discs for high-pressure systems |

Custom Features:

- Punching capacity: 5 Tons; Stripping capacity: 5 Tons

- 5” Bore, 2 ½” Rod Parker hydraulic cylinder as main ram equipped with an anti-rotation device

- Skid mounted power system and reservoir

- Kidney loop filter/cooler circuit with TEFC motor mounted oil cooler

- Calculated Ram Speeds: Pressing: 0-23 IPM; Return: 0-31 IPM

- Two hand operation with feather touch hand lever and safety palm button providing infinitely variable speed

- Dwell capability