| Tonnage | 50 | ||

| Application | Bending & Straightening | ||

| Industry | Agriculture | ||

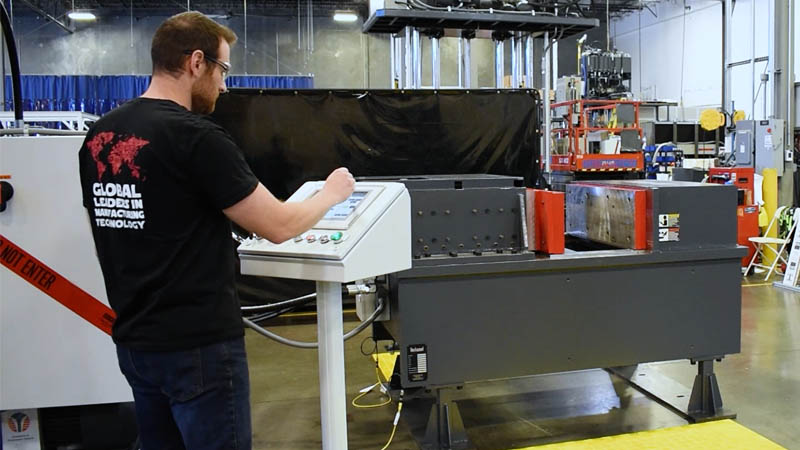

| Frame Style | Gib-Guided | ||

| Special Features | • Integrated into a fullyautomated workcell featuring a pre-heat oven, robots, and an automated chute for easy, touch-free part unloading | ||

| Intended Use | Used to form rotary blades for agricultural equipment |

Custom Features:

- Integrated into a fully-automated workcell featuring a pre-heat oven, robots, and an automated chute for

easy, touch-free part unloading - Ram bolster guided by an adjustable gib guidance system

- Skid mounted power system and reservoir

- Ram Speeds: Pressing: 197 IPM, Return: 402 IPM

- Kidney loop filter/cooler circuit with thermostatically controlled fan motor

- Safety mats on both sides stop ram motion when contacted